From Tracks to Rollers: Discovering a Wide Range of Komatsu Undercarriage Parts

From Tracks to Rollers: Discovering a Wide Range of Komatsu Undercarriage Parts

Blog Article

Boost Productivity With Undercarriage Parts and Its Makes Use Of

Recognizing the detailed elements that comprise the undercarriage of hefty machinery is critical for firms intending to enhance their operational effectiveness. From track footwear to gears and idlers, undercarriage parts play a crucial role in the performance and durability of devices. The tactical usage of these elements can bring about significant enhancements in efficiency and price savings. Let's discover just how businesses can harness the power of undercarriage parts to improve their procedures and drive success in an affordable market.

Relevance of Undercarriage Components

Routine upkeep and timely substitute of undercarriage components are vital to avoid expensive downtime and take full advantage of productivity. Worn-out undercarriage parts can lead to minimized grip, enhanced gas consumption, and increased wear on other components of the equipment. By buying high-quality undercarriage components and sticking to a strict upkeep routine, operators can optimize the efficiency of their hefty equipment and expand its solution life.

Usual Sorts Of Undercarriage Components

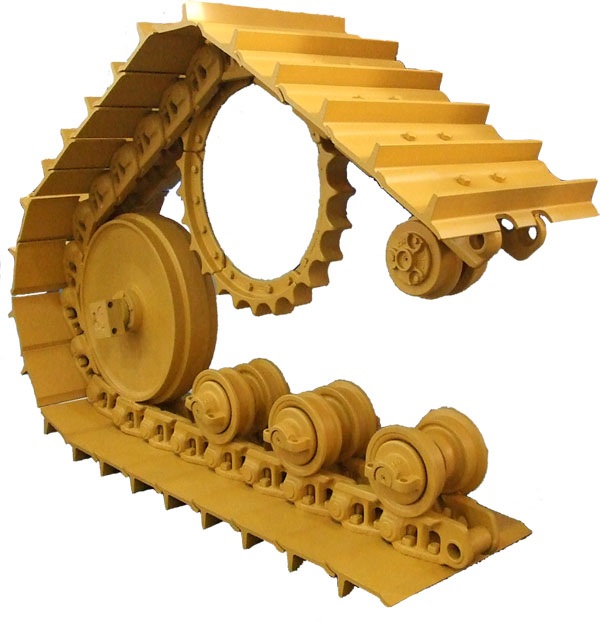

Vital components crucial for the effective procedure of hefty machinery, undercarriage components play an important duty in guaranteeing optimum performance and durability of the tools. Some typical kinds of undercarriage components consist of track chains, track shoes, rollers, idlers, gears, and track frames. Track chains are accountable for sending the machine's weight and offering traction, while track shoes support the device's weight and safeguard the track chain from wear. Rollers help in assisting the track and boosting its sturdiness, while idlers help control the track tension and minimize wear on the track system. Sprockets engage with the track web links and provide the driving force for the machine's activity. Ultimately, track structures work as the primary framework sustaining all the undercarriage components. Recognizing the function and importance of these usual undercarriage components is important for maintaining hefty machinery in optimal functioning problem, minimizing downtime, and making the most of productivity on job websites. Normal assessment, upkeep, and timely substitute of these elements are essential consider guaranteeing the overall performance of heavy tools.

Benefits of Routine Maintenance

Enhancing operational efficiency and extending tools lifespan, regular maintenance of undercarriage components is crucial for optimizing heavy machinery performance. By sticking to an organized maintenance timetable, operators can avoid expensive failures and lessen downtime. Regular inspections and maintenance of undercarriage elements such as tracks, rollers, idlers, and sprockets not only make certain smooth procedure but additionally contribute to overall security on work websites.

Enhancing Devices Efficiency

In addition, choosing the ideal undercarriage parts for details operating problems is essential. Elements such as the kind of surface, workload, and ecological conditions need to be taken into account when selecting undercarriage parts. Making use of high-grade parts that are created to stand up to the demands of the task can improve total devices content efficiency and durability.

Moreover, keeping undercarriage components well-lubricated and tidy is essential for smooth operation. Dirt, debris, and lack of lubrication can create premature deterioration on elements, leading to decreased efficiency and possible malfunctions. Normal cleansing and lubrication regimens can assist prevent these issues and guarantee constant devices efficiency.

Cost-efficient Solutions for Services

To maximize undercarriage components efficiently and make sure long-lasting equipment performance, companies have to prioritize economical solutions that align with their functional needs and spending plan restraints. Purchasing top notch undercarriage parts can result in significant savings over time by reducing downtime, upkeep costs, and the threat of unforeseen equipment failings. One economical service for companies is to apply an aggressive maintenance schedule that consists of regular evaluations, lubrication, and timely substitute of worn-out undercarriage parts. By recognizing and resolving prospective issues early on, businesses can protect against pricey fixings and prolong the life expectancy of their devices.

An additional cost-effective technique is to resource undercarriage components from trusted providers that offer a balance between top quality and price. These distributors typically supply affordable pricing, warranty choices, and sped up delivery services, aiding companies minimize procurement prices and decrease tools downtime. Additionally, services can discover alternate undercarriage components such as aftermarket elements that fulfill market criteria and specs at a lower expense than OEM parts. By thoroughly evaluating their alternatives and partnering with reputable distributors, companies can successfully handle their undercarriage part expenditures without jeopardizing on efficiency or dependability.

Verdict

In conclusion, undercarriage components play an essential duty in enhancing tools performance and efficiency. It is clear that undercarriage components are crucial elements for businesses looking to improve performance and preserve their equipment in ideal condition.

From track footwear to gears and idlers, undercarriage components play a vital function in the performance and durability of equipment.The importance of undercarriage parts in heavy machinery can not be overstated, as they are essential elements that substantially impact the check this site out overall efficiency and durability of the equipment.Essential parts crucial for the efficient operation of heavy equipment, undercarriage components play an essential function in making sure optimum efficiency and durability of the devices.Enhancing functional effectiveness and extending devices life expectancy, routine maintenance of undercarriage parts is essential for optimizing hefty equipment efficiency. In addition, organizations can explore alternative undercarriage parts such as aftermarket components that meet market criteria and requirements at a lower expense than OEM components.

Report this page